Turbine Blade Design Project

The following outlines a Blade Design project I worked on with Krista Roessle, Aleira Sanchez, and Max Taubman in MAE 4272: Fluids and Heat Transfer Laboratory at Cornell University.

Executive Summary

Context and Objectives

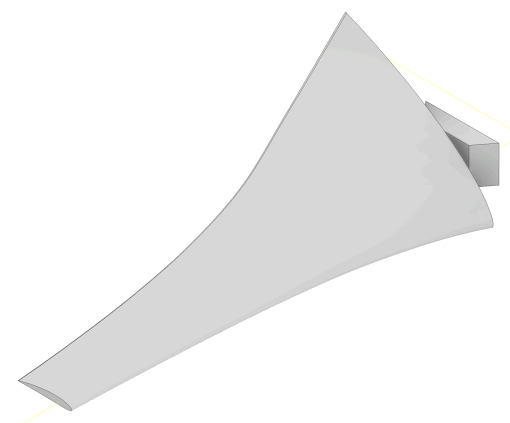

The team designed a blade based on NACA 4412 airfoil geometry, with a final length of 6 inches that had optimized chord length and pitch angle. Maximum power generation was the team’s ultimate goal, and design work was based on a far-field wind velocity of 4.73 m/s, as described by the Weibull distribution, and a rotation rate of 1200 rpm.

Design Process

The chord length and pitch angle optimization of the airfoil geometry was based on calculating the average Reynolds number across the entire blade, updating the angle of attack and ensuring it maximized the CL/CD ratio, and taking these parameters to derive equations for chord length and pitch angle as a function of blade radius. A CAD model was then generated with parameterization of these equations, which allowed for the model to be easily changed throughout the design process. Bending stress and torque analysis of the preliminary design was conducted and ensured that our design would not catastrophically fail during testing.

Testing Procedure

The team approached data collection through conducting an RPM sweep from 1800 - 0 RPM at selected wind speed. This data collection was then repeated for multiple wind speeds from 3.0-5.4 m/s, and took place over 2 testing days.

Discussion

The blade in experimentation generated a maximum of 3.98 W at a wind speed of 4.8 and rotational rate of 1570 rpm, and notably with a maximum torque brake of 3.6 oz-in. This was far different than the original design objectives of 4.7 m/s, 1570 rpm, and 0.0588 oz-in. Likely causes for this discrepancy include setbacks during data collection, limitations in the maximum RPM allowed to be used with the experimental setup, and issues with the torque brake. For future iterations, the blade would be designed around an optimal rotational rate of 1550 rpm and the same wind speed of 4.7 m/s, ensuring that more power will be generated for this system and loading conditions.

Conclusion

The team successfully designed the blade around the goal of maximizing power output through optimizing chord length and pitch angle. Experimentally, the blade generated a maximum power output of 3.98 W at 4.8 m/s and 1570 RPM, and the blades did not catastrophically fail during data collection. The team ultimately worked well together, with each member taking on responsibilities that aligned with their strengths. Future work includes improving data collection by including a more robust RPM sweep and updating blade parameters to better reflect the experimental rotation rate of 1570 RPM.