What is Wiski Fins?

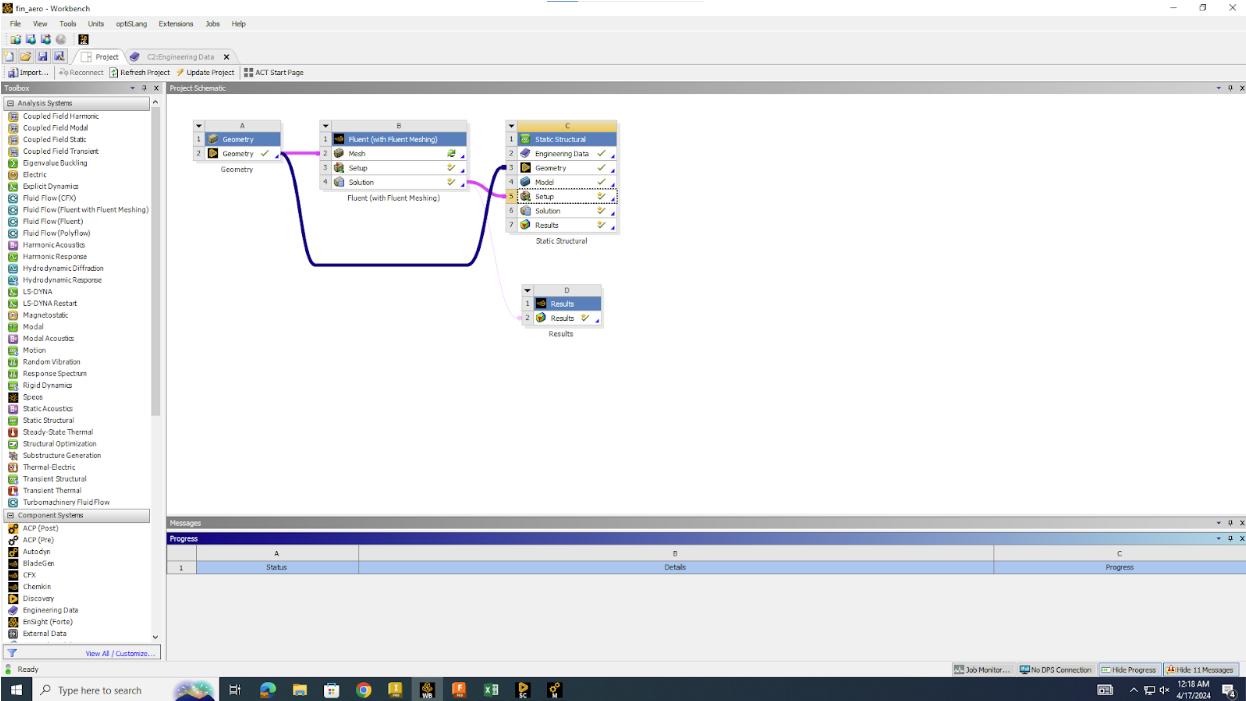

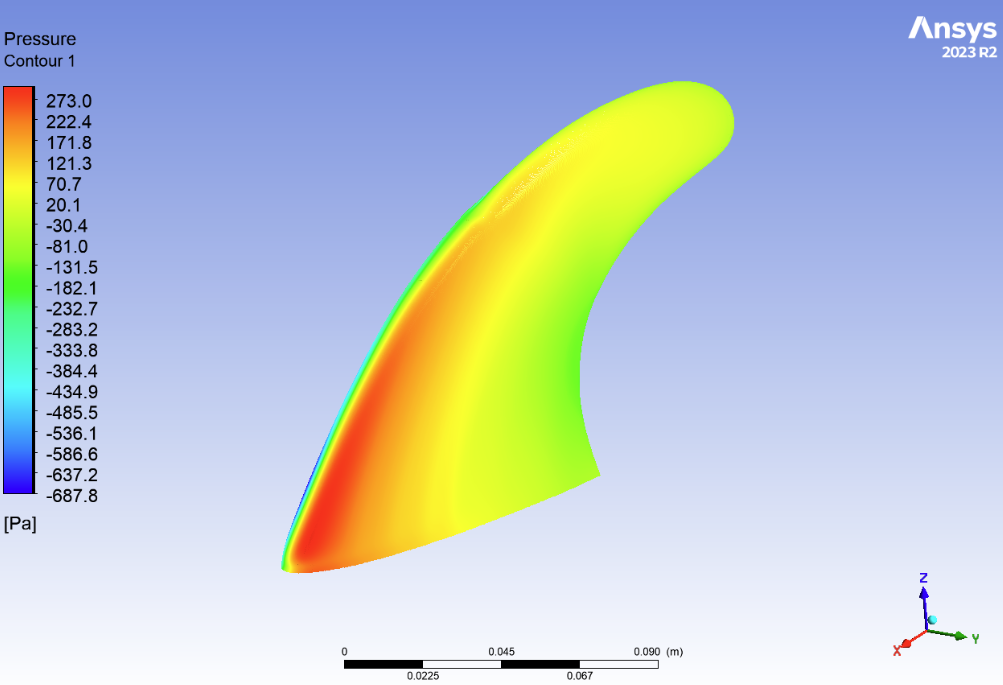

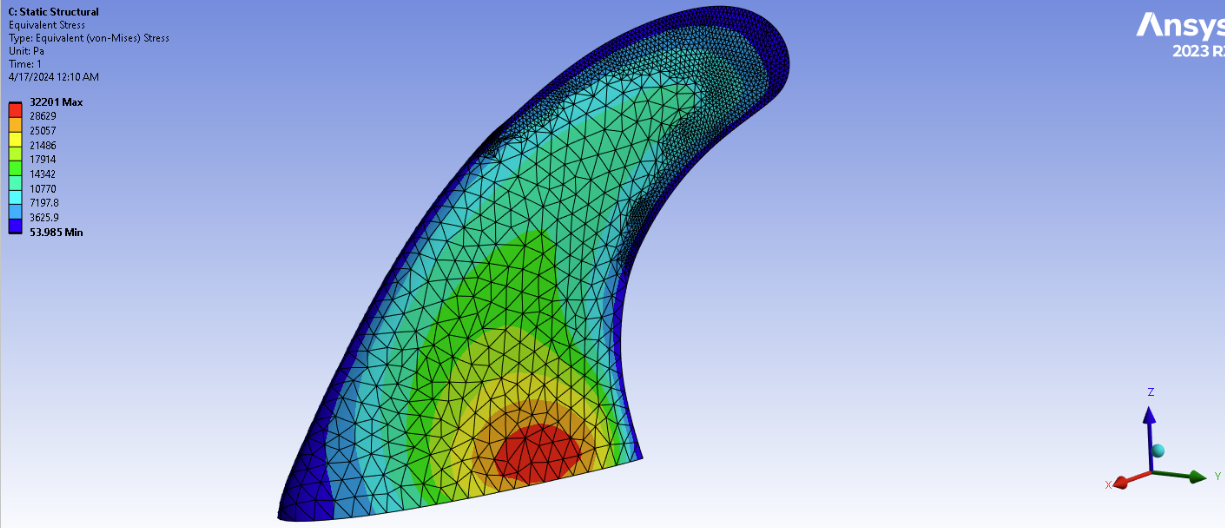

Initially a gift for my younger brother, I optimized Surfboard fins for his size, weight, and existing surfboards. I then optimized hydrodynamic efficiency during turning through the use of CFD and Structural FEA analysis and manufactured the fins using the Forged Carbon Fiber manufacturing process. Eventually, my brother and I created Wiski Fins, and started selling fins to friends and are in negotiations with local surf shops. So far, we've sold 12 sets of fins at $69 each, netting over $800 in revenue and over $500 in profit!

Personal Background

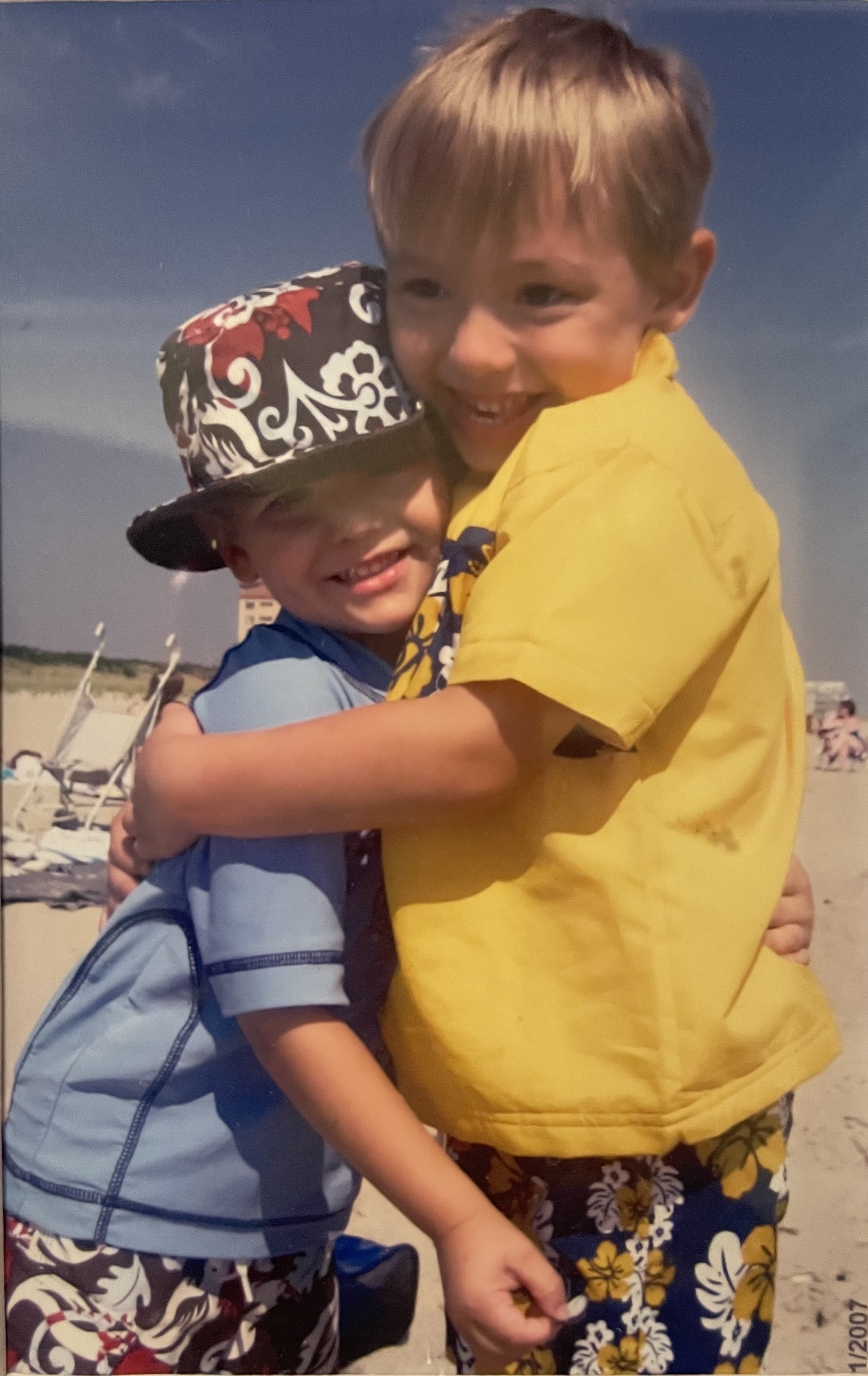

Me and my little brother, Nicky, have been going to the beach our whole lives. Over the years, we've built award winning sandcastles, boadyboarded with dolphins, established a rainbow-loom bracelet empire,

and of course, surfed! Ever since I've left for college in 2021, Nick has been surfing even more and was looking into some board upgrades. Unfortately, FCS and futures have a complete monopooly on the fin

market so a good set of carbon fiber fins cost around $150.

Me and my little brother, Nicky, have been going to the beach our whole lives. Over the years, we've built award winning sandcastles, boadyboarded with dolphins, established a rainbow-loom bracelet empire,

and of course, surfed! Ever since I've left for college in 2021, Nick has been surfing even more and was looking into some board upgrades. Unfortately, FCS and futures have a complete monopooly on the fin

market so a good set of carbon fiber fins cost around $150.

Technical Motivation

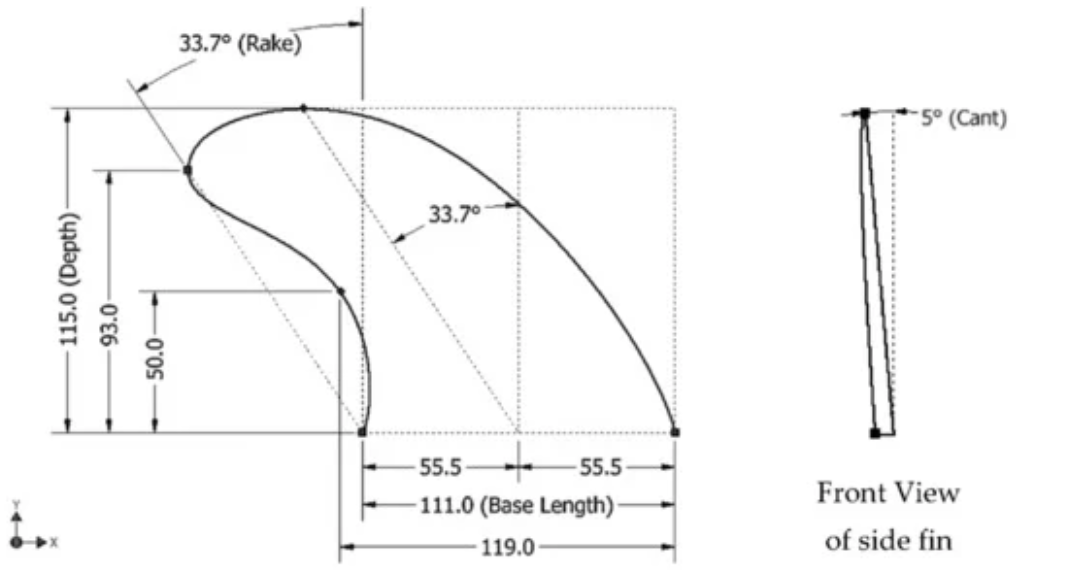

While I love Surfing and bodyboarding, the engineering part of me reels back whenever engaging with the surfing discourse around board and fin design. Almost all of the guides or differences between different boards and fins are characterized heavily by "Bro Science", making almost all decisions based on trial and error and feel. This always rubbed me the wrong way from an enginerring mindset, but I also didn't have the time, hundreds of dollars to test a variety of different fin designs and styles, and access to an ocean in Ithaca, NY or Milford, MI.

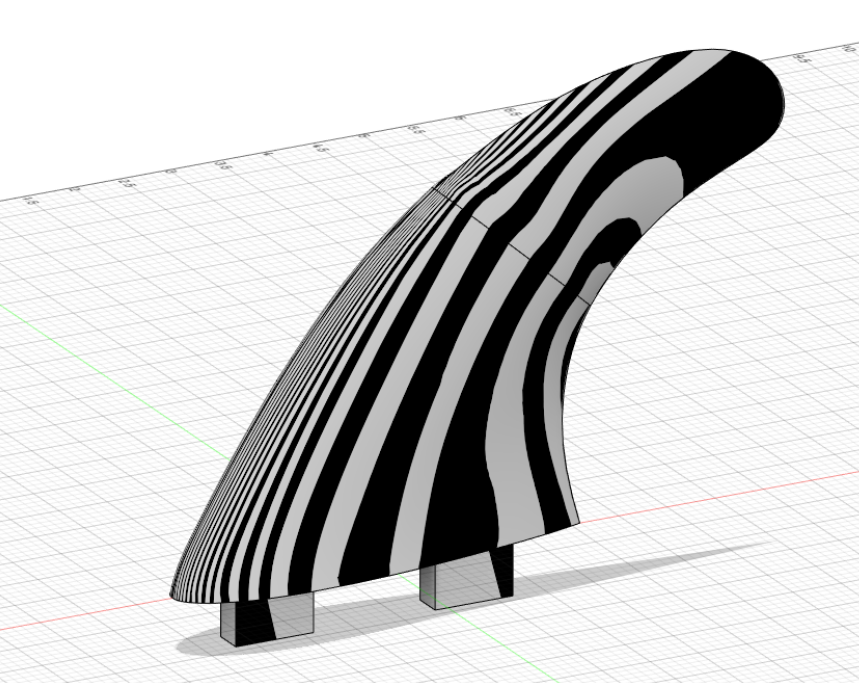

Coming into this project, I had extensive experience working with Carbon Fiber and FEA analysis through my project team, so I settled on some goals for this project: Give my little brother a kickass birthday present (Due Date: Sept 21st), Design a brand new fin using engineering design principles, Conduct more CFD and Sturctural Analysis on Surfboard Fins than seemingly anyone else before, Manufacture these myself and inexpensively, Do this all while working full time during my Internship at General Motors. Seems easy!