Carbon Fiber Fins

This is an old project and I’m not happy with it. Thus is I reworked things on my new fin page

Initially a gift for my younger brother, I optimized surfboard fins for his size, weight, and existing surfboards. I then improved hydrodynamic efficiency during turning through the use of CFD and Structural FEA analysis and manufactured the fins using the Forged Carbon Fiber manufacturing process. Now I’ve made several sets and have sold some to friends/mutuals. Me and my brother are now trying to sell more through some local surf shops.

Personal Background

My little brother, Nicky, and I have been going to the beach our whole lives. Over the years, we’ve built award-winning sandcastles, bodyboarded with dolphins, established a rainbow-loom bracelet empire, and of course, surfed! Ever since I left for college in 2021, Nick has been surfing even more and was looking into some board upgrades. Unfortunately, FCS and Futures have a complete monopoly on the fin market, making a good set of carbon fiber fins cost around $150.

Technical Motivation

While I love surfing and bodyboarding, the engineering part of me recoils at the “bro science” that dominates discussions about board and fin design. Almost all decisions are based on how it feels rather than structured engineering principles. I didn’t have the time, hundreds of dollars, or access to an ocean while studying in Ithaca, NY, or working in Milford, MI, to test a variety of fin designs myself.

Given my experience working with carbon fiber and FEA analysis through my project team, I set some goals for this project:

- Give my little brother a kickass birthday present (Due Date: Sept 21st).

- Design a brand new fin using engineering principles.

- Conduct more CFD and Structural Analysis on Surfboard Fins than seemingly anyone else before.

- Manufacture the fins myself at low cost.

- Complete all of this while working full-time during my internship at General Motors.

Design, Analysis, and Manufacturing

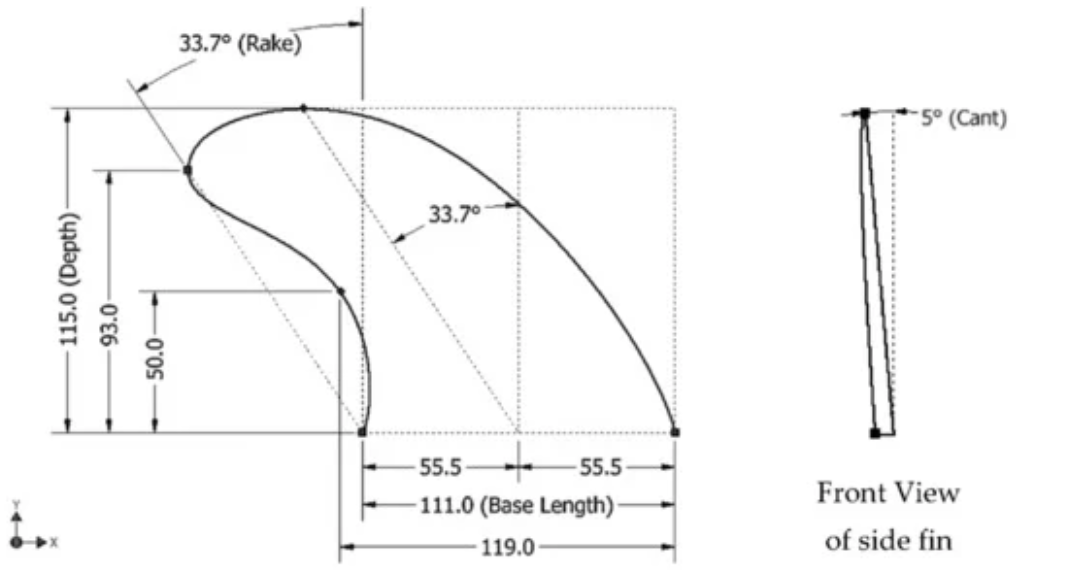

Fin Design

Most surfboard fins are designed around the FCS or Futures fin box system, which means once you choose one, you’re stuck with it. Since I was designing for my brother’s favorite board, I went with the FCS fin box design.

Almost every surfboard fin uses a low-digit NACA Airfoil, but I suspected a thicker airfoil might perform better at high Angles of Attack (AoA). I designed both a Fat Fin and a Skinny Fin to compare them using CAE analysis.

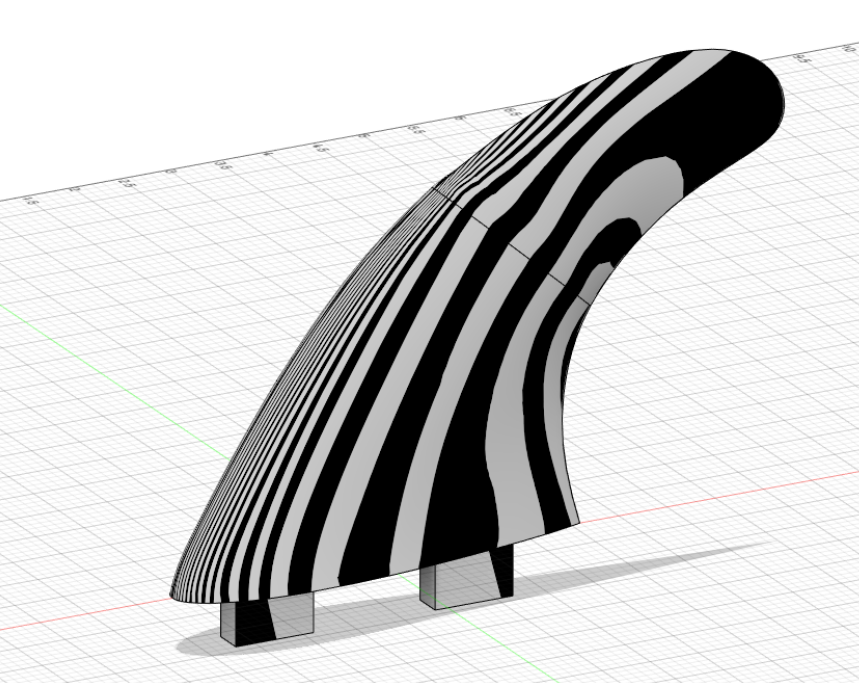

After establishing my master model, I created my fins using surface modeling tools in Fusion 360, ensuring G2 surface continuity with the Zebra tool.

General Fin Design Parameters. I created a Master Model based on these parameters for rapid design iteration! I currently alter my designs based on airfoil type and base length.

Fin CAD Render

Zebra analysis of surface demonstrates G2 continuity throughout the fin, ensuring smooth fluid flow over the surface.

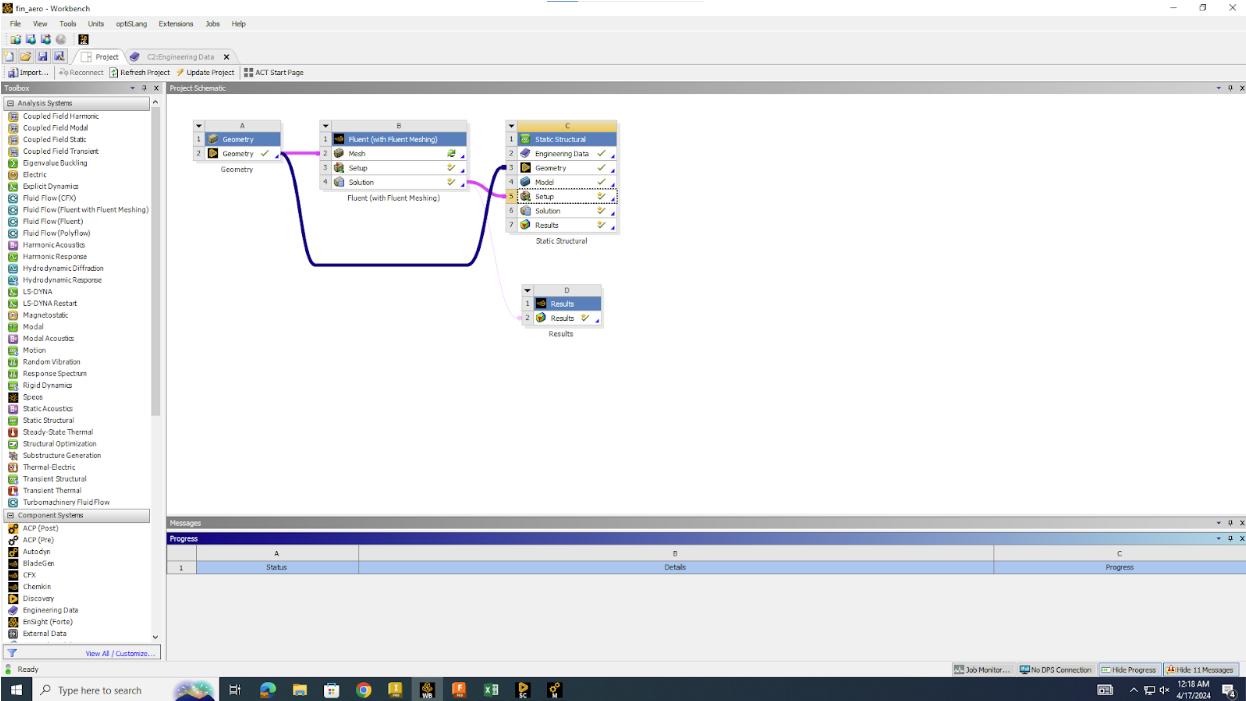

CAE Analysis

I first analyzed the hydrodynamic performance of my fin under extreme conditions, particularly when turning on a massive wave. Failure in this scenario would be catastrophic (big splash), so I wanted to ensure the fin could still maneuver properly.

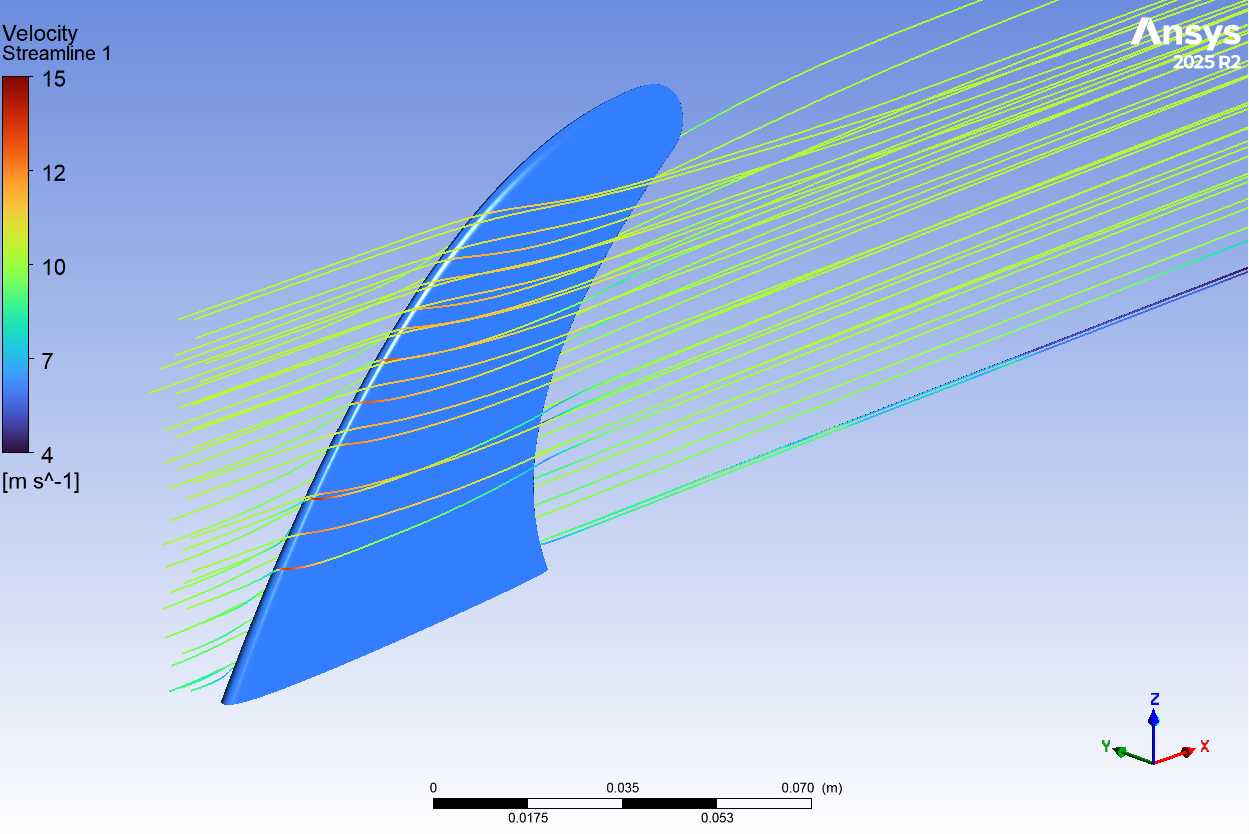

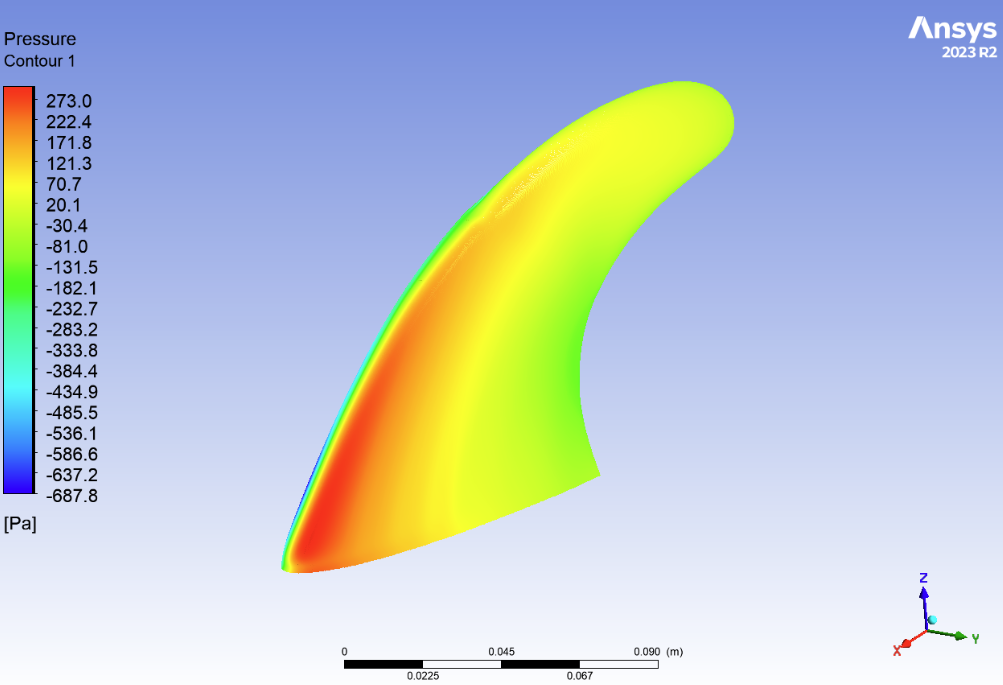

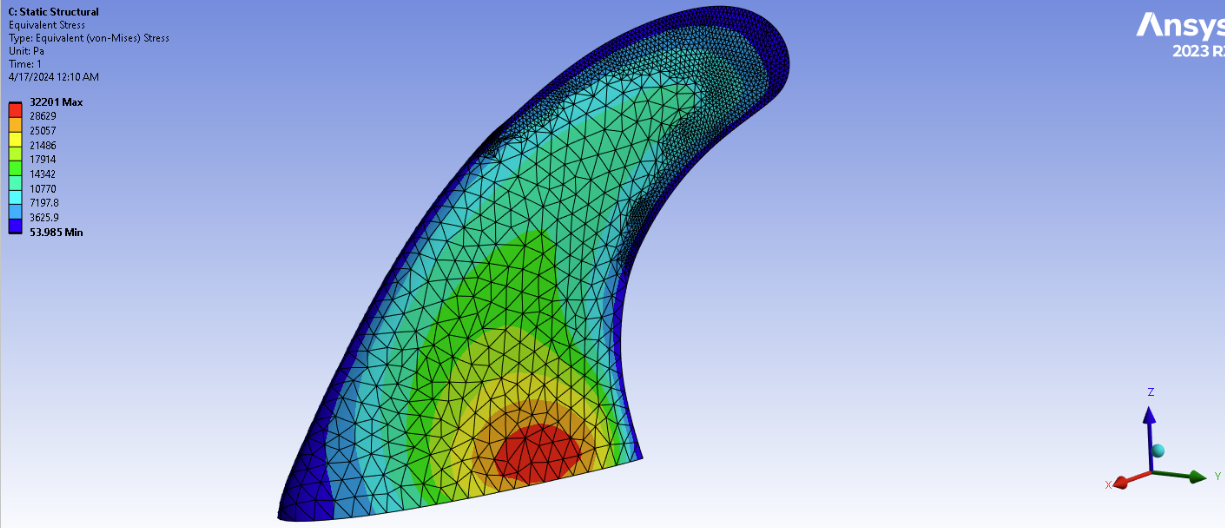

I exported pressure data from Ansys Fluent and imported it into Ansys Mechanical to accurately model complex forces on the fin.

Key Findings:

- Fat Fin: At 25 m/s (~50 mph), it generated 0.88 N of Drag and 1.9 N of Lift.

- Skinny Fin: At 25 m/s (~50 mph), it generated 0.92 N of Drag and 2.76 N of Lift.

These results surprised me, as the Cl/Cd ratios from airfoil tools suggested the opposite. After confirming that the Skinny Fin could withstand extreme loads with a Factor of Safety (FOS) of 6.25, I decided to manufacture the Skinny Fin instead. This was particularly impactful as its volume is ~50% less than the Fat Fin, leading to a ~50% reduction in material costs.

Ansys Workbench Workflow: CFD Analysis in Fluent and then mapping pressure contours into Ansys Mechanical for Structural Analysis.

Velocity Streamlines of the water in Ansys Fluent.

Pressure contours of the fin in Ansys Fluent.

Stress Analysis based on mapped pressure contours.

Manufacturing

To achieve my goal of making inexpensive carbon fiber (an oxymoron) surfboard fins, I used the Forged Carbon Fiber Method, which combines:

- Chopped carbon fiber tow

- Ambient-cure epoxy

- 3D printed molds

This method was initially developed by Lamborghini and iterated upon by Easy Composites.

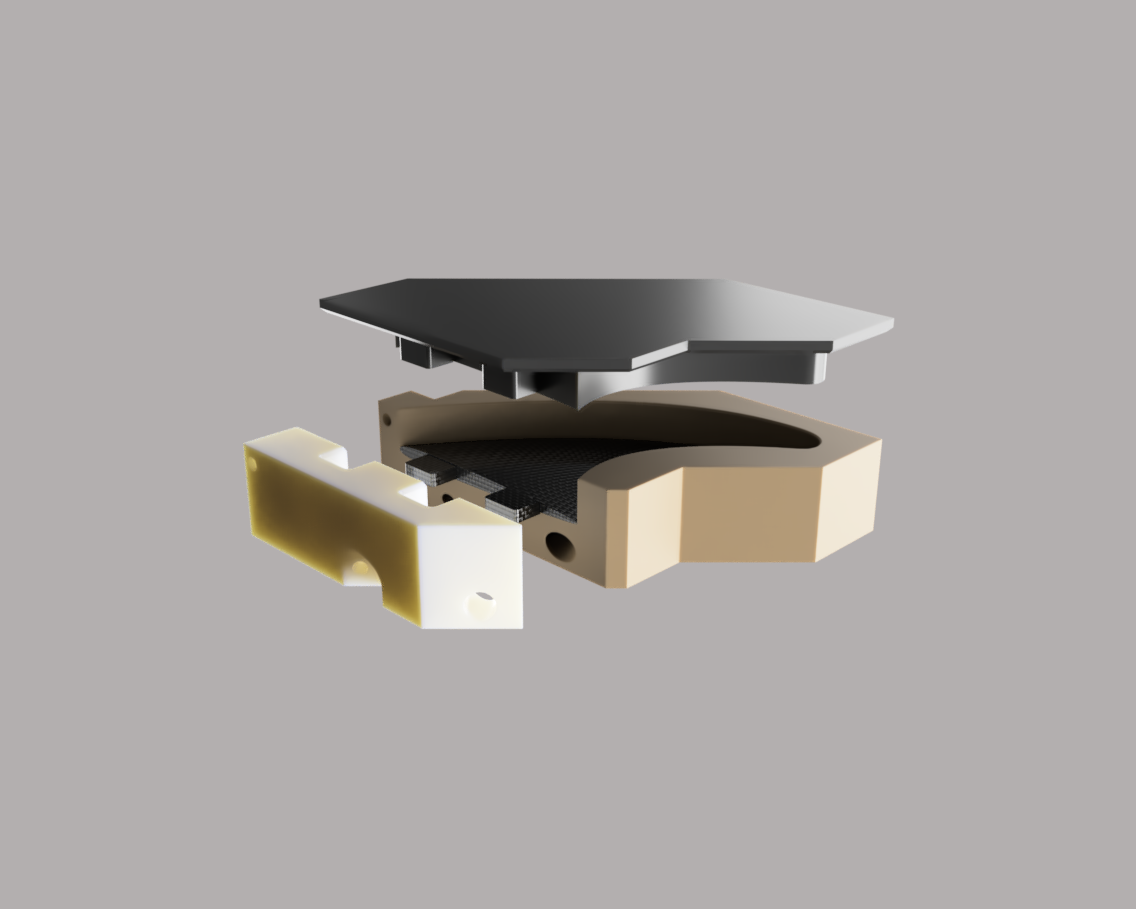

I designed split molds based on my fin model, using:

- Boolean tools

- Offsets, draft angles, and chamfers

- Holes for mounting hardware

To withstand orging pressure and demolding, I printed the molds with 75-60% infill using PETG filament, which also prevents binding to the epoxy.

Mold Design

The first successful fin prototype!

Fin layup process.

Fin extraction after curing.

Conclusion

What started as a birthday gift for my brother turned into a fully engineered, tested, and manufactured surfboard fin with a little business on the side, too. I’ve optimized performance through CFD and FEA, successfully manufactured fins at a fraction of market prices (~$20 vs $150), and even started selling them to friends and other local surfers.