ZT Group

Nano Heat Energy Research Laboratory at Cornell University

Introduction

Over the Summer of 2023, I started working as an undergraduate researcher in ZT Group, a Nano Heat Energy Research Group at Cornell.

I worked primarily with PhD Candidates Joyce Christiansen-Salameh and Gustavo Alvarez under Dr. Zhiting Tian.

Throughout the summer, I worked on three different projects.

Hexagonal Boron Nitride Characterization

The first project aimed to identify and catalog the out-of-plane thermal properties of the 2D Material, Hexagonal Boron Nitride (h-BN).

Why This Matters

The ultimate goal of this project is to gauge the efficacy of h-BN as a potential material to mitigate vibrational energy spread in quantum computers.

Superconducting qubits are an emerging platform for quantum technologies, but large-scale quantum computing is limited by qubit coherence time.

One major source of decoherence arises from high-energy non-equilibrium phonons (excess vibrational energy).

Our work aims to:

- Reveal underlying processes governing phonon-induced decoherence in superconducting qubits.

- Use fundamental knowledge to design novel mitigation strategies.

- Evaluate the effectiveness of these strategies by fabricating and characterizing superconducting qubit devices.

Why h-BN?

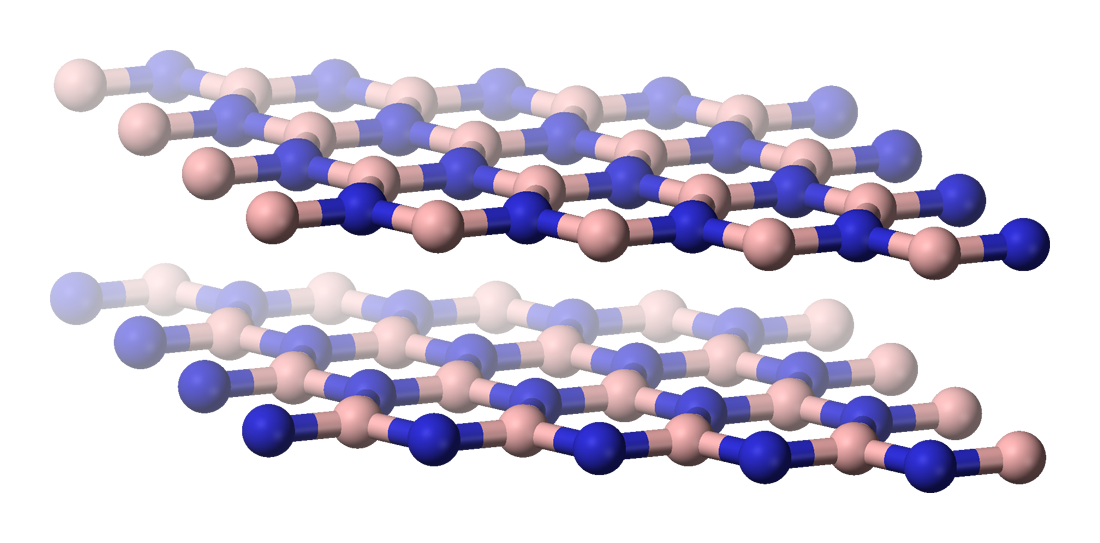

Hexagonal Boron Nitride is unique because:

- Its in-plane thermal conductivity is high and well-documented.

- Its out-of-plane thermal conductivity is significantly lower, but not well understood.

To study this, I worked with frequency-domain thermoreflectance laser systems to categorize the energy dissipation rate.

Atomic Structure of Hexagonal Boron Nitride

—

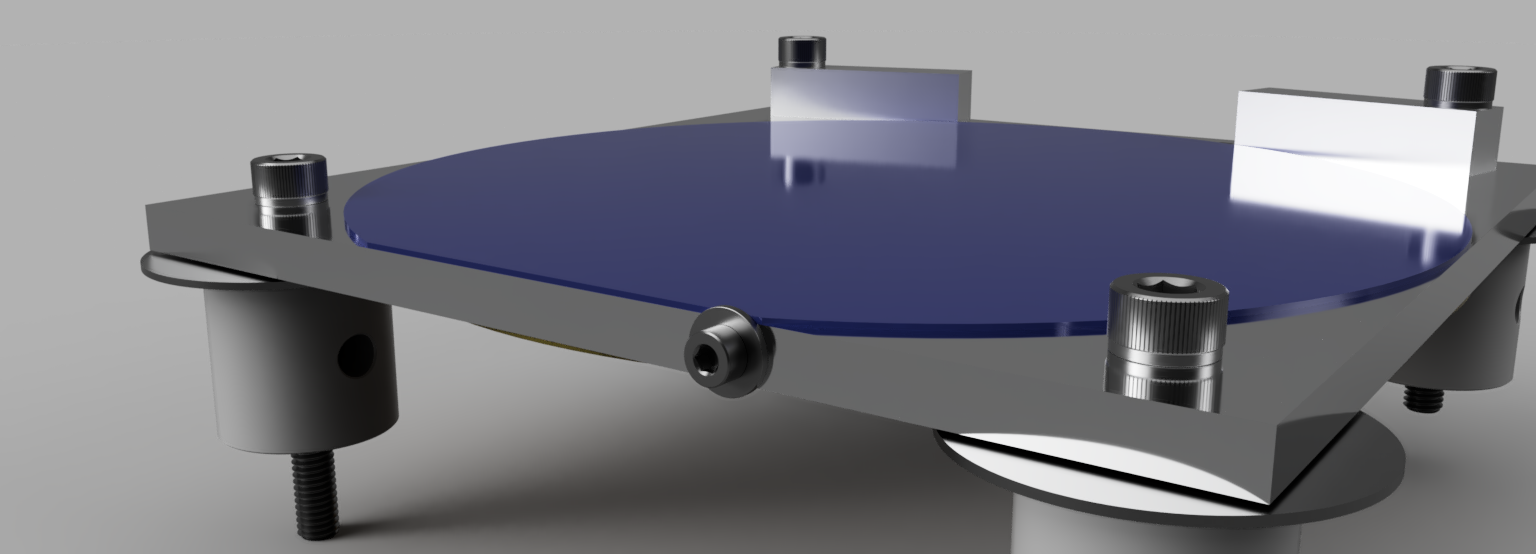

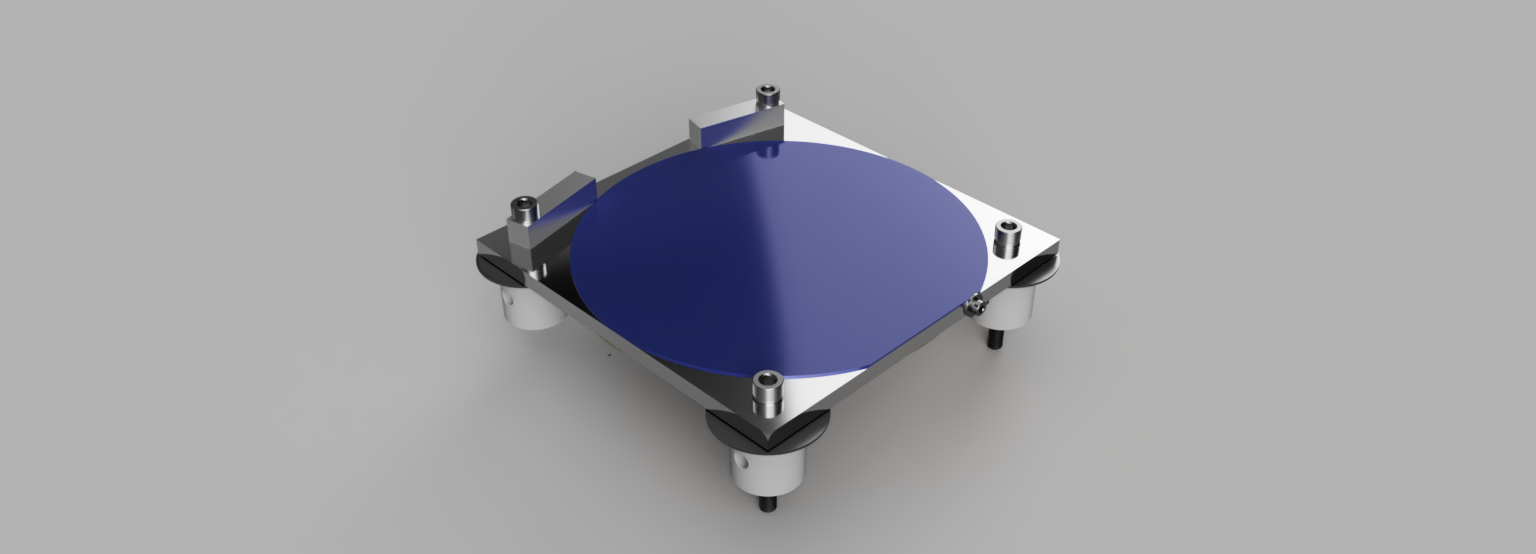

Dry Transfer Stage Design & Manufacturing

The final project involved designing a Dry Transfer Stage to transfer h-BN samples from glass slides to a silicon plate with:

- High precision

- Various dynamic variables (e.g., temperature variation, delicate mounting methods)

Design Challenges

- Silicon plate stability:

- The plate placement must be consistent over time.

- It must be flush and level, but clamps/adhesives can’t be used because silicon is fragile and brittle.

- Temperature constraints:

- The silicon plate must reach 200°C while ensuring that precise movement controls stay under 40°C.

- Solution:

- Minimized object profile and protrusions for ample transfer/observation space.

- Implemented PID controller and thermocouple for rapid and precise temperature control.

Dry Transfer Stage CAD Render

Dry Transfer Stage CAD Render

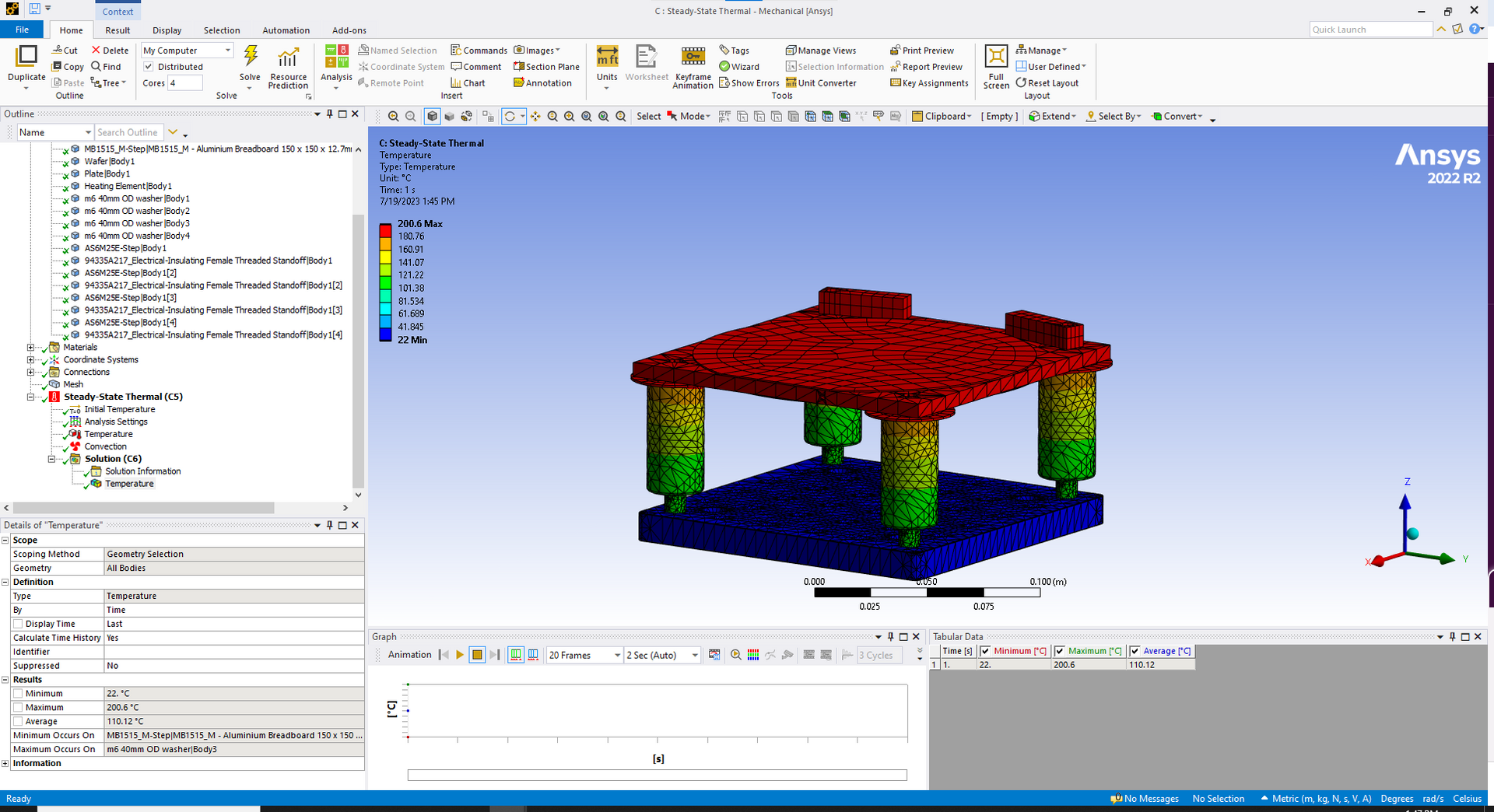

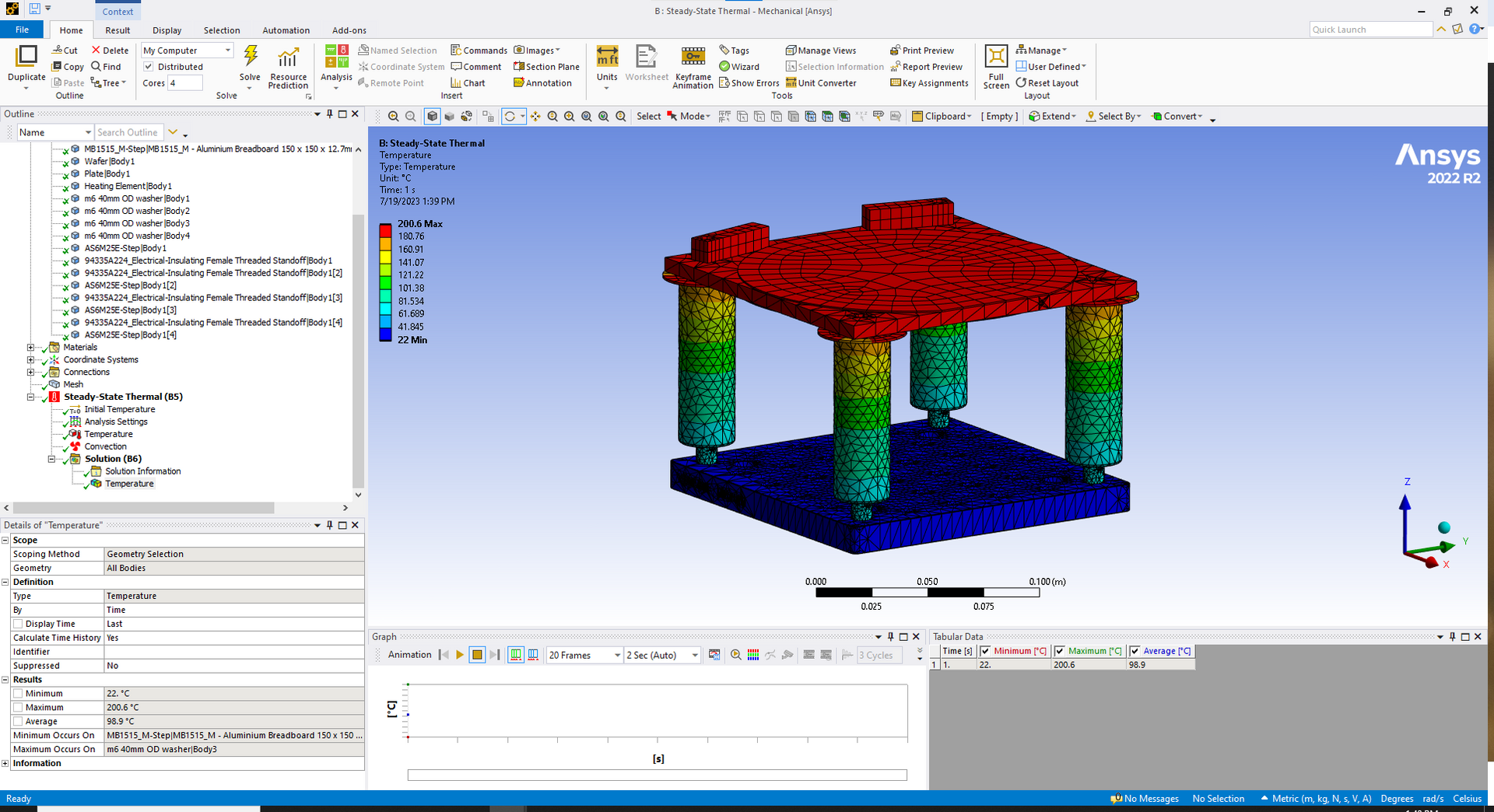

Thermal Analysis

Ansys Thermal Analysis across various ceramic standoff heights

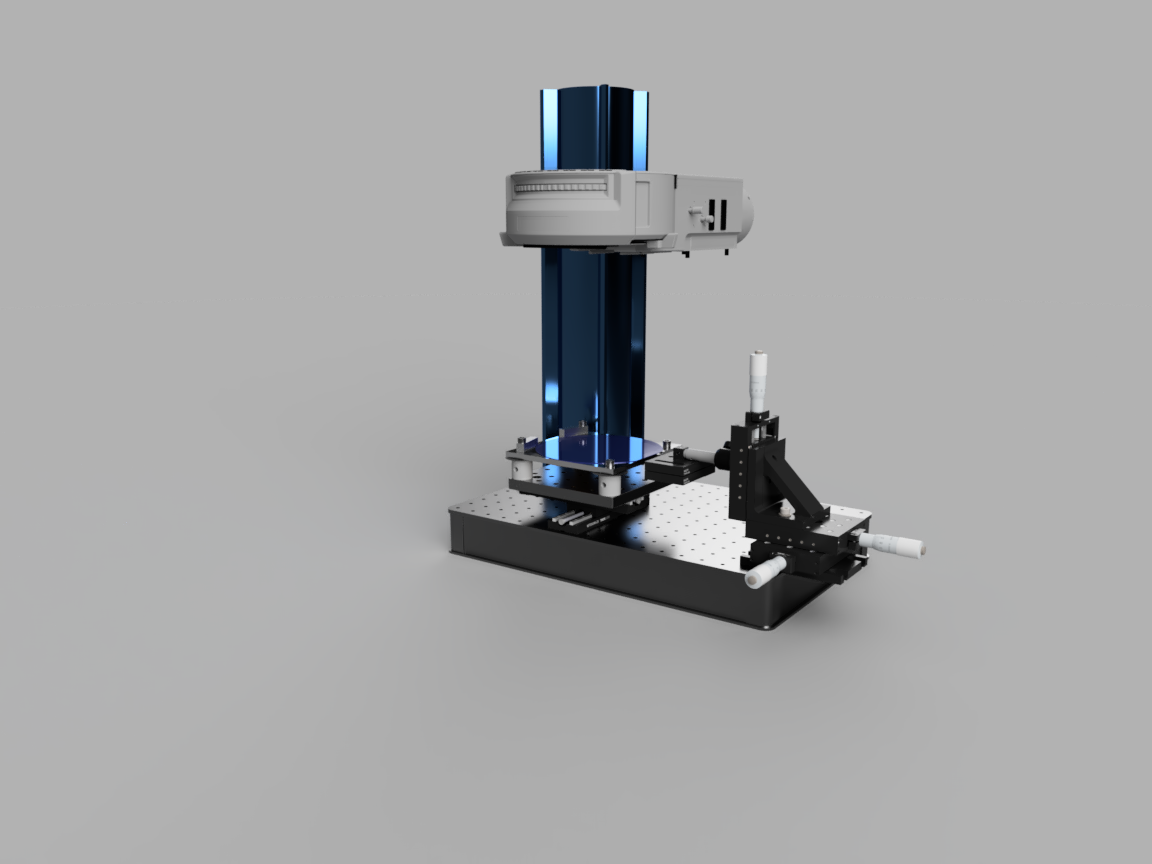

Hexagonal Boron Nitride Synthesis

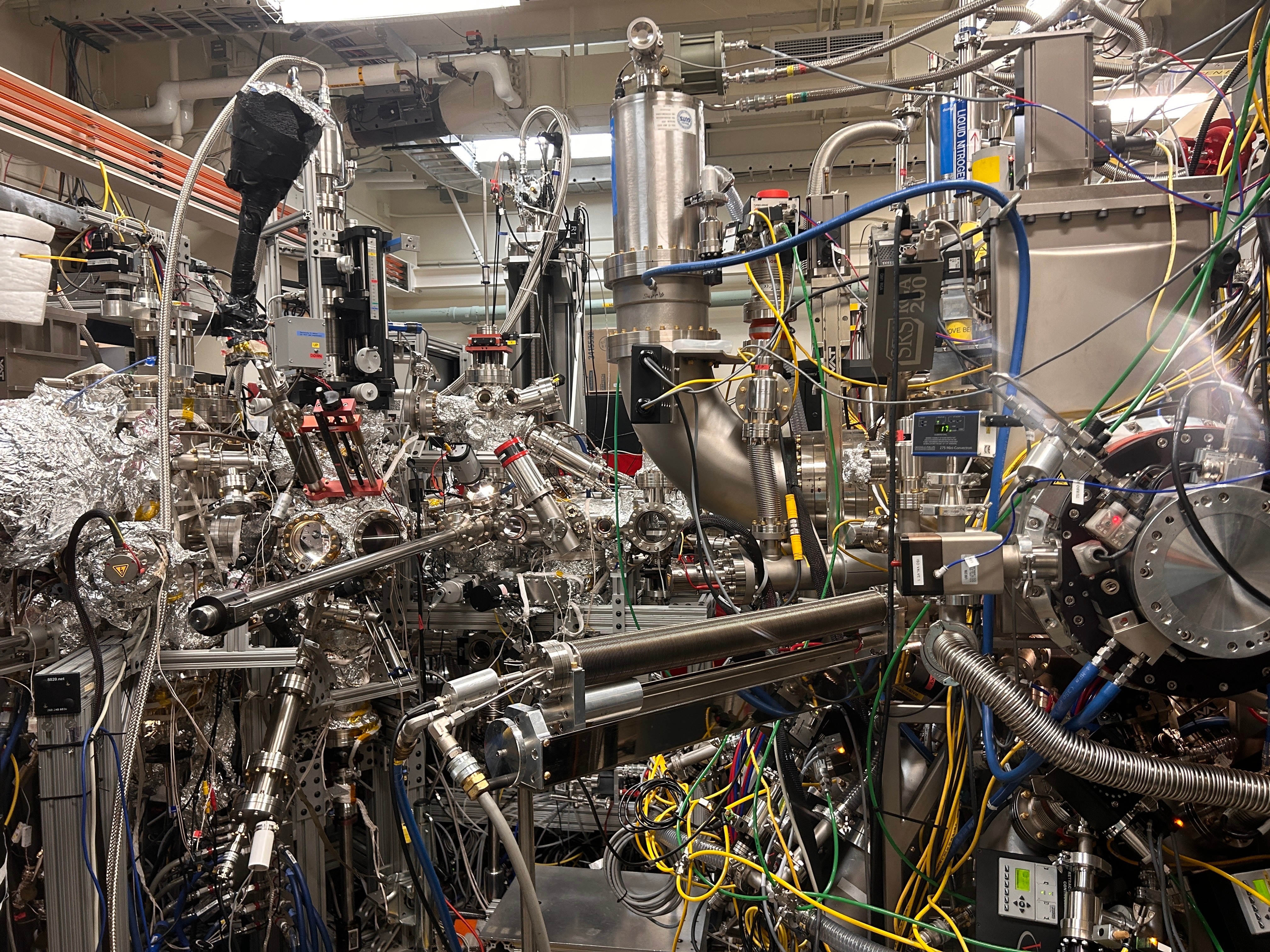

For this project, I worked on the synthesis of h-BN using molecular beam epitaxy (MBE).

Research Process

- I was the only undergraduate in a team of PhD students, Post-Docs, and Professional Scientists.

- To contribute meaningfully, I read and annotated 10+ research papers on:

- The specific niche of h-BN crystal synthesis.

- The broader field of quantum material synthesis.

Key Discovery

- I identified irregularities in the required E-Beam power level throughout synthesis.

- The power output continuously increased, indicating an unexpected issue.

- This led to the discovery of boron supply erosion, which was damaging the crucible.

- By catching this early, we avoided $250,000+ of dollars in damage.

PARADIM Molecular Beam Epitaxy Laboratory